Machine Calibration

|

notice |

|

|---|---|

|

|

Installation of the system must be fully completed before calibrating the system. |

A profile wizard starts automatically and must be completed the first time which the steering module is accessed after installation or any time the ECU![]() Electronic Control Unit is reset.

Electronic Control Unit is reset.

Refer to Reset Calibrated Gains for additional information about resetting the steering system.

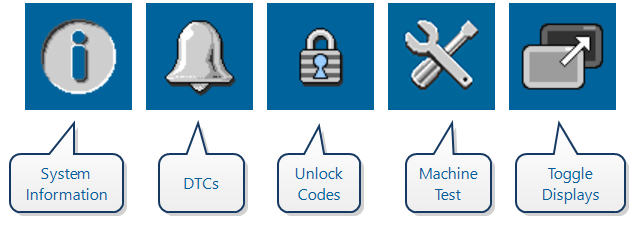

Note: System Information, Diagnostic Trouble Codes (DTCs), and Machine Test screens may be viewed during the initial calibration process. Refer to the following topics for additional assistance with the settings available during the initial calibration wizard.

Note: The Machine Test icon will only be displayed if a steering partner is detected.

Preparation and Best Practices

- For best performance, the steering system must be calibrated specifically for each machine configuration (e.g. tractor and implement combination).

- Ensure that the tractor and corresponding implement software versions are up-to-date with required versions.

Note: PCM/Pro 1200 requires software version 4.58 or higher. SC1™/IDU

Implement Drive Unit requires 25.1 or higher.

Implement Drive Unit requires 25.1 or higher.

- Ensure that the tractor and corresponding implement software versions are up-to-date with required versions.

- Start the calibration process with the machine parked on a level surface with several acres of smooth ground available.

- Ensure that the engine and hydraulic systems are at normal operating temperature and perform all calibration procedures at typical operating RPM.

- It is recommended to calibrate in conditions as close to actual field operations as possible. Before starting the calibration process:

- Fold and rack booms on self-propelled applicators.

- Disconnect any implements from the tractor hitch. Best results are obtained by completing the machine calibration without any towed implements.

- Verify machine measurements are correctly entered into the UT

A Universal Terminal (formerly Virtual Terminal) is an electronic display or console capable of interfacing with ECUs on an ISOBUS network..

A Universal Terminal (formerly Virtual Terminal) is an electronic display or console capable of interfacing with ECUs on an ISOBUS network..

- During the auto-steering calibration, the machine will make several hard left and right turns. Adjust the vehicle speed and location as necessary.

- To pause the calibration at any time, turn the steering wheel or press the Stop button on the UT. Tap the foot/resume switch to resume the calibration process.

- To ensure successful auto-steering calibration, try to minimize the number of pauses.

- If an error message is displayed during calibration, refer to Diagnostic Trouble Codes (DTCs) for possible causes and corrective action steps to be taken.

|

|

|

|---|---|

|

|

The machine will steer automatically. Be sure the area around the vehicle is clear of people and obstacles before engaging the auto-steer system. To disengage auto-steering at any time, toggle the roading switch, select the on-screen Stop button, or (as applicable) turn the steering wheel. |

|

|

|

|---|---|

|

|

During the auto-steering calibration, the machine will make several hard left and right turns. Adjust the vehicle speed and location as necessary. |

|

notice |

|

|---|---|

|

|

Calibration of the machine steering system should be performed in a field or other large, open space and with conditions similar to normal vehicle operation. If the ground or surface is slippery, muddy, or freshly tilled, the auto-steering system may learn incorrect steering responses for normal operating conditions. Ensure the machine hydraulics are operating properly and there are no other mechanical issues which may affect performance of the steering system. |

Initial calibration of the RS1™ or SC1™/TC1™ system consists of the following component setup calibrations:

- Guidance and GNSS Calibration

- Terrain Compensation Calibration

- Auto-Steer Calibration

- Steering Control Calibration

Note: The SC1™/TC1™ system can be used for GPS only or for GPS and auto-steering. The following sections walk through the calibration procedures for both GPS only as well as GPS guidance and auto-steering.

Last Revised: Sep 2024

warning

warning